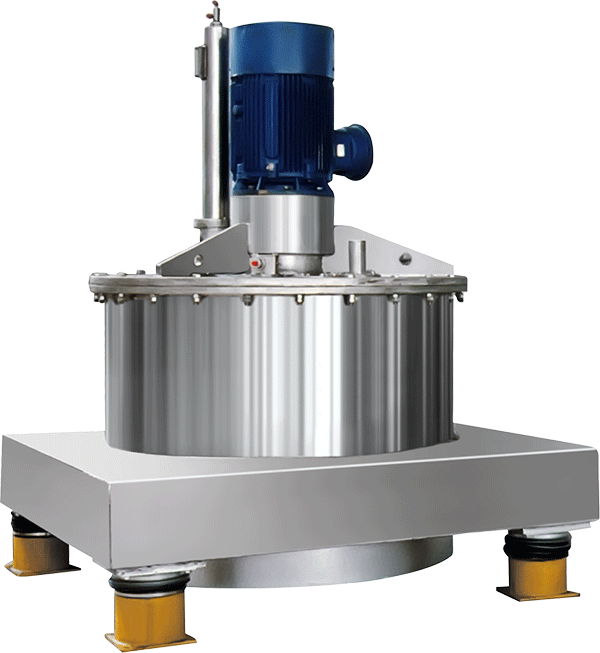

Factory spot supply of Hengrui direct PSD1200 vertical lifting bag discharge filter plate centrifuge

Products Description

PSD type centrifuge adopts mechanical assisted discharge, which not only has the characteristics of high efficiency of automatic scraper centrifuge, but also has the advantages of wide applicability of unloading centrifuge, advanced product structure design, small footprint, low failure rate, and high cost performance.

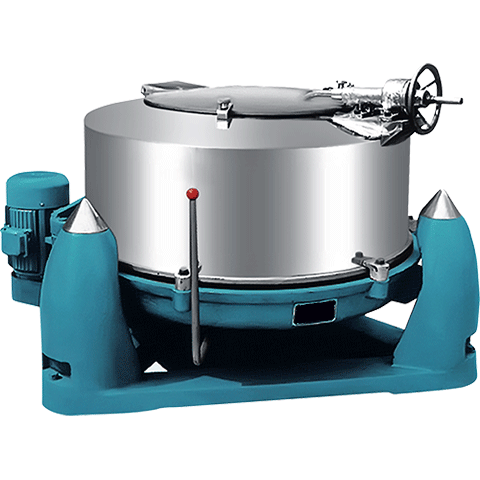

PSD centrifuge is an improved product based on SS type tripod upper discharge centrifuge. In addition to retaining the advantages of SS centrifuge, it also significantly reduces the labor intensity, fast discharge, easy to clean the filter bag, improves the production efficiency, and avoids the pollution and dispersion of the finished product caused by manual discharge.

Product Structure

Standard form of manufacture

1. Structure: Shell is equipped with clamshell, feed tube, washing tube, viewing mirror, exhaust port, lighting hole; Closed structure, drum and shell, clamshell and other parts are made of stainless steel material (SUS404).

2. All fasteners are stainless steel parts

3. Transmission and braking: ordinary motor (or explosion-proof motor) + inverter + energy consumption braking

4. Electric control device (control box)

5. Fluid damped shock absorber

6. The machine is equipped with a set of special spreader

Matching device

Clean the spray system

Nitrogen protection system

According to the anti-corrosion requirements of the user's separated materials, the corresponding stainless steel material (SUS304, 316, 316L, etc., or titanium (TA)) is used.

Overactuating protection

Open cover protection device

Field explosion-proof button

Work Program

PSD centrifuges are closed type, intermittent operation, lifting bag off-site discharge of filtration equipment. The material is added to the drum from the upper part, the liquid phase passes through the filter medium and is discharged from the machine under the action of centrifugal force field, and the solid phase is trapped in the drum. After shutdown, the liquid baffle and filter bag are lifted out together with the lifting tool. Unloading to site. It has the characteristics of smooth start, adjustable separation factor, large capacity, high efficiency, convenient operation, fast discharge, good safety performance, clean environment and low labor intensity.

The PSD type centrifuge eliminates the traditional hanging leg, adopts the plate counterweight and the high viscosity damping vibration isolator to absorb the vibration, and has no foundation installation.

Product Parameter

Main Features

1. Use frequency converter to start, start smoothly, and the separation factor is adjustable

2. Loading and unloading materials, low labor intensity, high efficiency

3. Reasonable structural design, effective removal of sanitary dead corners, structural parts are too smooth, the surface is polished, external structural parts, fasteners and drum body are made of stainless steel. The shell is clamshell type, which can clean the space between the centrifuge shell and the drum.

4. Optional cleaning spray system can be configured to clean the centrifuge online, the inner wall of the centrifuge shell, the surface of the drum, the surface of the liquid collecting tank and other invisible parts of the centrifuge. Comply with the requirements of GMP specification for equipment.

5. Simple structure, easy operation and maintenance.

6. The grain is not easily broken.

7. Optional nitrogen protection system is configured to ensure that the centrifuge cavity is isolated from the outside air.

8. Strong versatility, wide range of application.

9. Sealed structure, the sealing parts are silicone rubber or fluorine rubber. It can realize the requirements of sealing and explosion-proof, and is suitable for toxic and flammable and explosive applications.

10. Structure: The shell is equipped with clamshell, feeding tube, washing tube, viewing mirror, lighting hole and sealing structure.

11. Transmission and braking: ordinary motor (or explosion-proof motor) + inverter + energy consumption braking.

Production Site

About Us

Zhangjiagang Hengrui Pharmaceutical Machinery Co., Ltd. is a vigorous company, founded in 2001, has its own strong factory, located in the beautiful Zhangjiagang city, Jiangsu Province, the factory area of 5000 square meters, the existing staff 60 people. The company mainly produces centrifuges, centrifugal extractors and other products, with an annual output of more than 500 sets and an annual output value of 30 million yuan.

Hengrui process control technology

We are committed to providing the most efficient and economical solid-liquid separation solutions to meet the needs of all customers. From the start of the project to the lifetime service of the equipment, customers will benefit greatly from our experts, advanced technical reliability and high quality override equipment.

Competitive power

Over the past 25 years, Hengrui Process Control Technology has become a leader in the separation equipment industry. The rich experience of our engineers comes from the realization of more than 2,000 products and more than 5,000 application cases, and more than 100 patents testify to our ability to innovate. This extensive empirical knowledge supports our methods and equipment recommendations, all of which are economical and performance optimized to meet your specific requirements.

- Description

- Related Products

Description

Products Description

PSD type centrifuge adopts mechanical assisted discharge, which not only has the characteristics of high efficiency of automatic scraper centrifuge, but also has the advantages of wide applicability of unloading centrifuge, advanced product structure design, small footprint, low failure rate, and high cost performance.

PSD centrifuge is an improved product based on SS type tripod upper discharge centrifuge. In addition to retaining the advantages of SS centrifuge, it also significantly reduces the labor intensity, fast discharge, easy to clean the filter bag, improves the production efficiency, and avoids the pollution and dispersion of the finished product caused by manual discharge.

Product Structure

Standard form of manufacture

1. Structure: Shell is equipped with clamshell, feed tube, washing tube, viewing mirror, exhaust port, lighting hole; Closed structure, drum and shell, clamshell and other parts are made of stainless steel material (SUS404).

2. All fasteners are stainless steel parts

3. Transmission and braking: ordinary motor (or explosion-proof motor) + inverter + energy consumption braking

4. Electric control device (control box)

5. Fluid damped shock absorber

6. The machine is equipped with a set of special spreader

Matching device

Clean the spray system

Nitrogen protection system

According to the anti-corrosion requirements of the user's separated materials, the corresponding stainless steel material (SUS304, 316, 316L, etc., or titanium (TA)) is used.

Overactuating protection

Open cover protection device

Field explosion-proof button

Work Program

PSD centrifuges are closed type, intermittent operation, lifting bag off-site discharge of filtration equipment. The material is added to the drum from the upper part, the liquid phase passes through the filter medium and is discharged from the machine under the action of centrifugal force field, and the solid phase is trapped in the drum. After shutdown, the liquid baffle and filter bag are lifted out together with the lifting tool. Unloading to site. It has the characteristics of smooth start, adjustable separation factor, large capacity, high efficiency, convenient operation, fast discharge, good safety performance, clean environment and low labor intensity.

The PSD type centrifuge eliminates the traditional hanging leg, adopts the plate counterweight and the high viscosity damping vibration isolator to absorb the vibration, and has no foundation installation.

Product Parameter

Main Features

1. Use frequency converter to start, start smoothly, and the separation factor is adjustable

2. Loading and unloading materials, low labor intensity, high efficiency

3. Reasonable structural design, effective removal of sanitary dead corners, structural parts are too smooth, the surface is polished, external structural parts, fasteners and drum body are made of stainless steel. The shell is clamshell type, which can clean the space between the centrifuge shell and the drum.

4. Optional cleaning spray system can be configured to clean the centrifuge online, the inner wall of the centrifuge shell, the surface of the drum, the surface of the liquid collecting tank and other invisible parts of the centrifuge. Comply with the requirements of GMP specification for equipment.

5. Simple structure, easy operation and maintenance.

6. The grain is not easily broken.

7. Optional nitrogen protection system is configured to ensure that the centrifuge cavity is isolated from the outside air.

8. Strong versatility, wide range of application.

9. Sealed structure, the sealing parts are silicone rubber or fluorine rubber. It can realize the requirements of sealing and explosion-proof, and is suitable for toxic and flammable and explosive applications.

10. Structure: The shell is equipped with clamshell, feeding tube, washing tube, viewing mirror, lighting hole and sealing structure.

11. Transmission and braking: ordinary motor (or explosion-proof motor) + inverter + energy consumption braking.

Production Site

About Us

Zhangjiagang Hengrui Pharmaceutical Machinery Co., Ltd. is a vigorous company, founded in 2001, has its own strong factory, located in the beautiful Zhangjiagang city, Jiangsu Province, the factory area of 5000 square meters, the existing staff 60 people. The company mainly produces centrifuges, centrifugal extractors and other products, with an annual output of more than 500 sets and an annual output value of 30 million yuan.

Hengrui process control technology

We are committed to providing the most efficient and economical solid-liquid separation solutions to meet the needs of all customers. From the start of the project to the lifetime service of the equipment, customers will benefit greatly from our experts, advanced technical reliability and high quality override equipment.

Competitive power

Over the past 25 years, Hengrui Process Control Technology has become a leader in the separation equipment industry. The rich experience of our engineers comes from the realization of more than 2,000 products and more than 5,000 application cases, and more than 100 patents testify to our ability to innovate. This extensive empirical knowledge supports our methods and equipment recommendations, all of which are economical and performance optimized to meet your specific requirements.