- Description

- Parameter

- Features

- How it works

- Related Products

Description

Product Overview

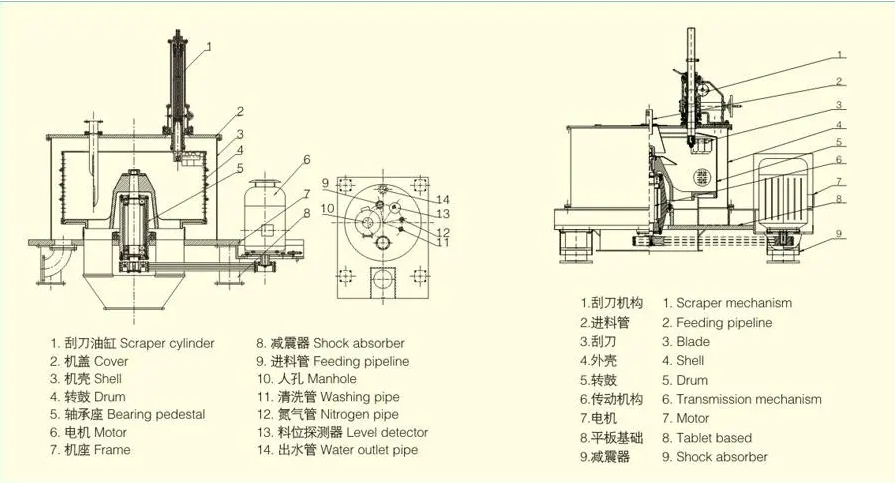

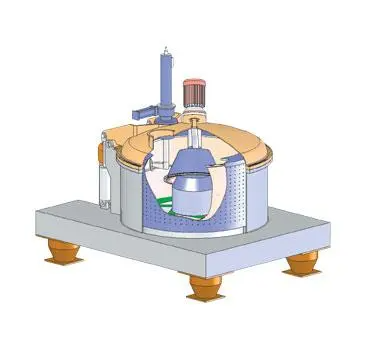

PGZ vertical scraper automatic discharge centrifuge

PGZ series centrifuge is a kind of automatic centrifuge with scientific structure design, high technical content, large processing capacity and convenient operation and maintenance. It is suitable for the solid-liquid separation of fibrous, suspension, high viscosity, fine particle size, toxic, flammable and explosive materials with solid content of 5% to 40%, with aseptic hygiene, sealed and explosion-proof, multiple safety protection, etc., it can be operated in plateau conditions, and has been widely used in pharmaceutical, fine chemical, new energy, food and other industries.

FEATURES AT A GLANCE

especially toxic, flammable and explosive materials and those materials with high viscosity and fine particle size. For example,

medical products such as antibiotics, vitamins and medical intermediates, food such as salt, monosodium glutamate, food additives,

starch, sugar and chemical seasoning, chemical materials, such as ammonium sulphate, gypsum, mirabilite, copper sulphate,

potassium chloride, borax, dye, pigment, resin and pesticide, and materials related to mining, metallurgy and environmental

protection industries, etc. The centrifuge can achieve remote control, with high automation and large handling capacity.

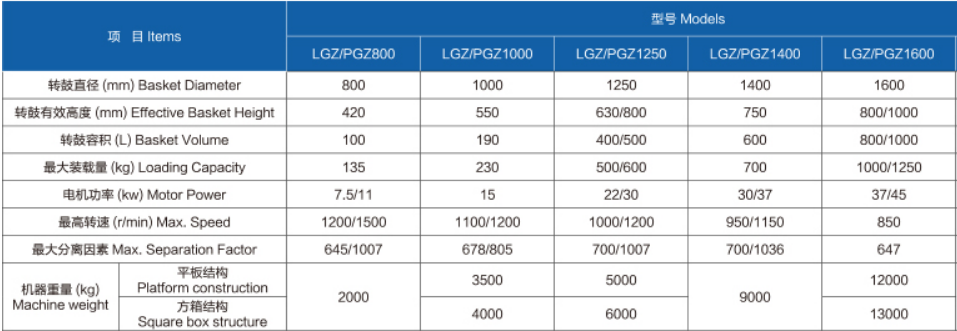

Parameter

|

Model |

Drum diameter |

Drum volume |

Maximum loading limit(Kg) |

Drum speed(R/min) |

Separation factors |

Motor power |

Dimensions(mm) |

The weight of the whole machine(Kg) |

|

LGZ/PGZ800 |

800 |

100 |

135 |

1200/1500 |

645/1006 |

7.5/11 |

1800x1200x2045 |

1800 |

|

LGZ/PGZ1000 |

1000 |

150 |

200 |

1000/1200 |

560/806 |

15 |

2000x1500x2150 |

2700 |

|

LGZ/PGZ1250 |

1250 |

280/400 |

400/500 |

900 |

567 |

22 |

2400x1800x2047 |

4500 |

|

LGZ/PGZ1500 |

1500 |

600 |

800 |

850 |

606 |

37 |

2900x2100x2700 |

7800 |

|

LGZ/PGZ1600 |

1600 |

775 |

1000 |

850 |

647 |

37 |

3000x2200x2700 |

8500 |

|

LGZ/PGZ1800 |

1800 |

1000 |

1200 |

800 |

645 |

45 |

3260x2300x2100 |

12000 |

Features

1. Smoother discharge

The automatic scraping device has the function of speed regulation and distance adjustment, and the scraper adopts a variety of structural designs such as double-edged (wear-resistant: alloy blades, wear-resistant coatings, etc.), optimizes the cutting angle, and the scraping resistance is small, and the layered scraping technology can be used for harder materials.

2. Run more smoothly

The liquid damping and vibration reduction technology is adopted, and the non-foundation installation form effectively reduces the vibration of the centrifuge and facilitates the installation and maintenance of the machine.

The square box design of the frame increases the weight of the chassis, reduces the center of gravity of the centrifuge, and reduces the vibration velocity.

3. The filter bag is quick to replace

Detachable drum liquid barrier design, self-locking and reliable, scientific filter cloth fixing module design (tensioning device + quick assembly structure), can quickly complete the filter cloth replacement.

4. Fully processed drum

100% weld flaw detection, high processing accuracy, large filtration area, conducive to the filtration of ultra-fine particles.

2. Fully enclosed structure

The material is completely isolated from the transmission, which meets the internal nitrogen filling protection of the equipment, effectively avoids material pollution, and ensures the safety of personnel.

6. Multiple security protection and guarantees

It has over vibration protection, overcurrent protection, temperature control protection, scraper in-situ protection, scraper stroke protection, cover opening protection, interlock protection, scraper lockdown protection, nitrogen protection, etc.

How it works

The lower discharge centrifuge of the scraper is a vertical automatic filter centrifuge. The motor drives the drum to rotate at high speed through the belt, and the material to be separated enters the centrifuge bowl with high speed rotation through the feeding system under the control of the pre-programmed program. Under the action of the centrifugal force field, the material is filtered through the filter medium (filter cloth/screen), the liquid phase is discharged out of the machine through the outlet tube, and the solid phase is trapped in the bowl. The material detection device detects the filling position of the material in real time, and stops feeding when the filter cake in the drum reaches the specified loading capacity of the machine. The cake is then washed and spun dry. After the filter cake reaches the dehydration requirements, the centrifuge is reduced to the scraping speed, and the scraper device scrapes the filter cake under the hydraulic (pneumatic) control, and discharges it through the discharge port at the lower part of the centrifuge.