- Description

- Parameter

- Features

- Related Products

Description

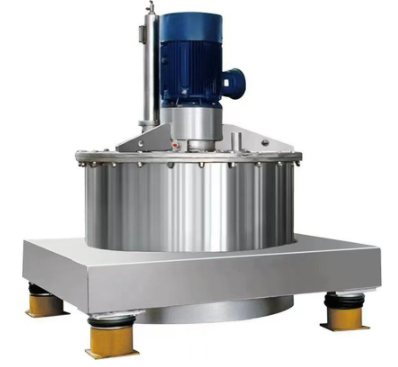

Products Description

PAUT series centrifuge is suitable for the washing and separation of solid and liquid phase of suspension medium containing solid particles, and also for the separation of solid and liquid phase of medium containing crystalline solid phase, and has a wide range of uses.

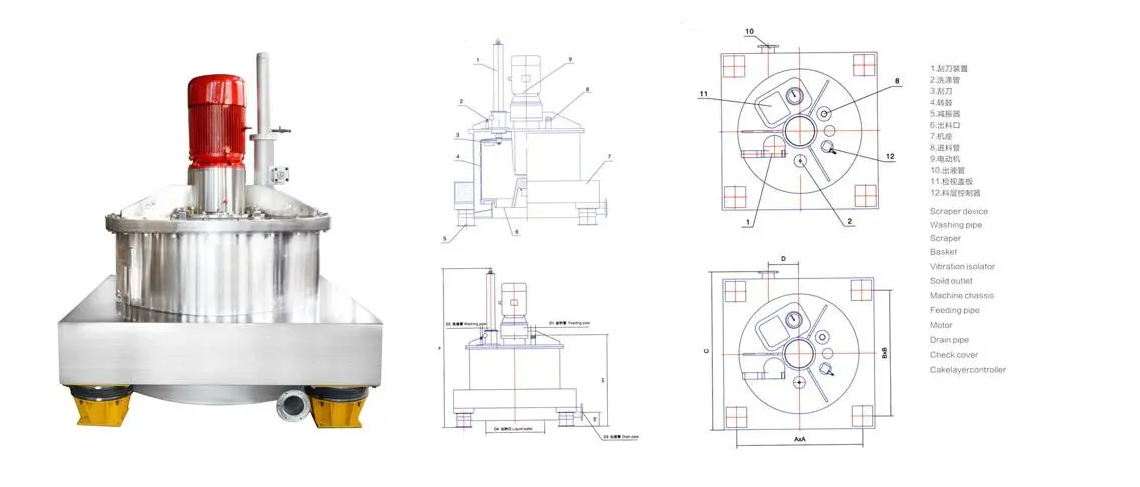

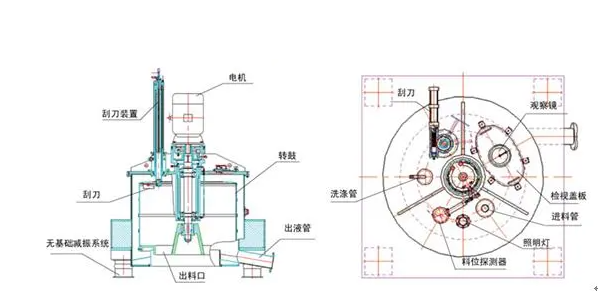

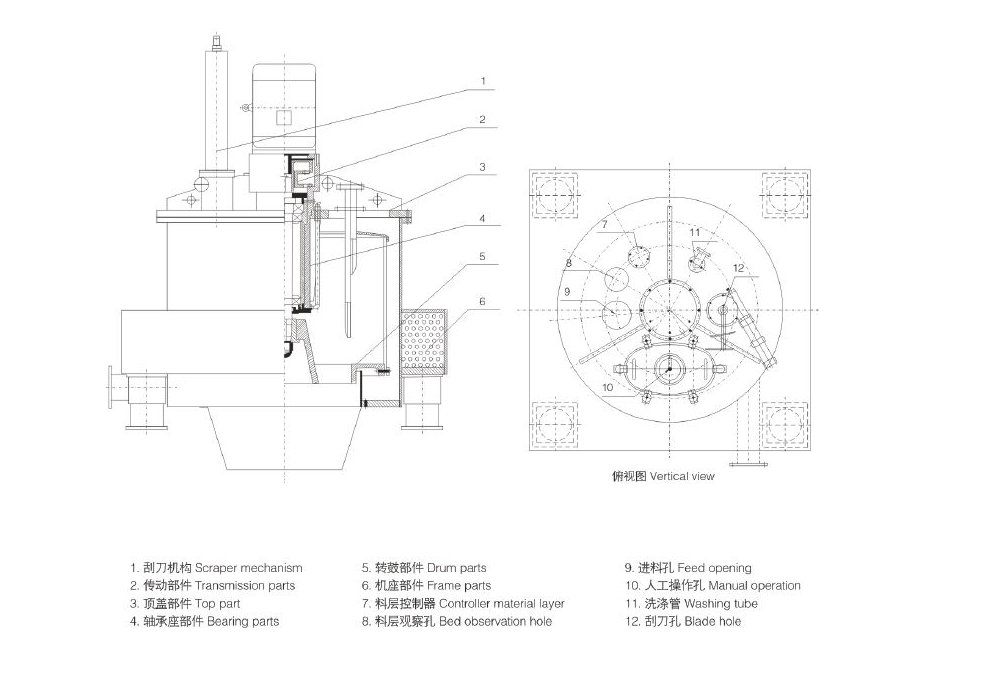

Product Structure

Main Features

Simple structure, smooth operation, good operation and shock absorption performance

Square box frame + liquid damping damper, low center of gravity, excellent damping effect. Independent bearing seat, bearing support span is large, drum center of gravity is low, bearing capacity is large, good operation performance. Full bearing structure of the body: good rigidity, simple structure, beautiful appearance.

Large clamshell structure and on-line cleaning device

According to the requirements of GMP, the centrifuge top cover is designed to be a large clamshell structure, which is more convenient for maintenance and filter cloth installation; A cleaning device is installed in the inner cavity of the centrifuge, which can be cleaned online when the centrifuge is running and preparing according to the process requirements.

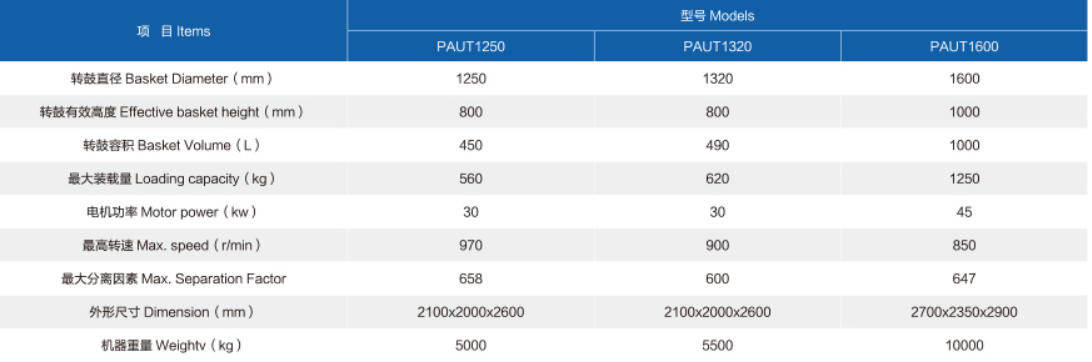

Product Parameter

Application Field

Chemical industry, such as lead powder, ethylene, tea, onion, ethylene calcanola, polypropylene, ABS resin, resin, bisphenol, sodium pentaphenol, sodium gasification, ferric sulfate, caustic soda, urea, ammonium sulfide, ammonium gasification, sodium perborate, modified starch, bleaching powder, triethyl hydrouric acid, etc.

Parameter

|

Model |

PAUT/AUT1250A |

PAUT/AUT1250B |

PAUT/AUT1320 |

PAUT/AUT1500 |

PAUT/AUT1600 |

|

diameter(mm) |

1250 |

1250 |

1320 |

1500 |

1600 |

|

Drum volume(L) |

281 |

450 |

490 |

653 |

900 |

|

Maximum loading limit(Kg) |

380 |

610 |

660 |

880 |

1200 |

|

Drum speed(R/min) |

970 |

970 |

900 |

800 |

850 |

|

Separation factor (ω2r/g) |

658 |

658 |

598 |

537 |

647 |

|

Motor power (kw.) |

22 |

30 |

30 |

37 |

45 |

|

Dimensions (mm) |

2100x2000x2235 2150x2000x2150 |

2000x1800x2600 2150x2100x2800 |

2050x1900x2600 2150x2100x2800 |

2450x2200x2800 |

2500x2500x2800 |

|

Machine Weight (kg) |

4200/3800 |

4800/4300 |

5000/4500 |

8500 |

10000 |

Features

1. Simple structure, stable operation, good operation and shock absorption performance

The uphang power direct connection structure, the transmission and drum rotation center coincide with the machine center, and the operation is stable.

Square box frame + liquid damping damper, low center of gravity, excellent damping effect.

Independent bearing housing, large bearing support span, low center of gravity of the drum, large bearing capacity, good operating performance.

The full bearing structure of the body: good rigidity, simple structure and beautiful appearance.

2. High efficiency and large processing capacity

Large aspect ratio, large charging volume.

The material has a wide range of applications.

3. Automatic control + multiple safety protection, and the operation of the equipment is more reliable

Fully automatic program control, reliable operation and high safety.

Frequency conversion speed regulation transmission is adopted, which starts smoothly and effectively protects the motor from overload.

Multiple safety protection + stepless layered scraping control.

4. Explosion-proof, anti-corrosion, anti-pollution

Fully enclosed structure, the motor is directly connected with the spindle, no belt drive, no friction dust pollution to the environment.

It can be equipped with nitrogen protection device to realize the application of explosion-proof occasions.

Anti-corrosion alloy materials and coating can be selected.