- Description

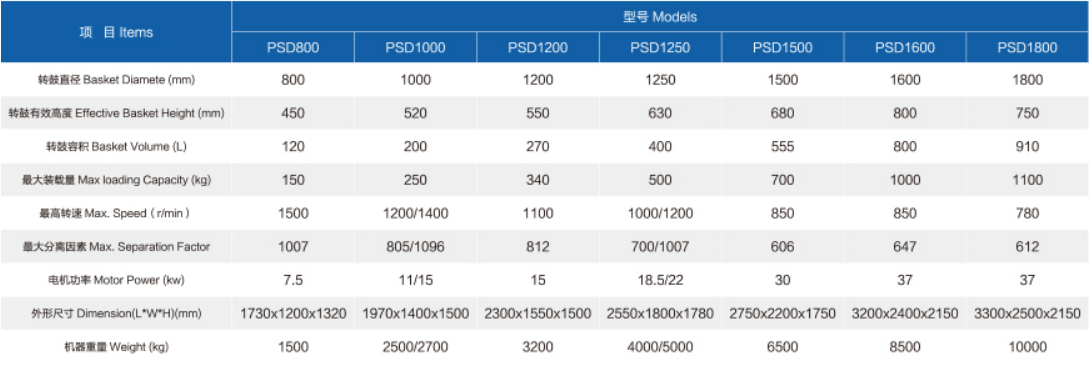

- Parameter

- Framework

- Features

- Related Products

Description

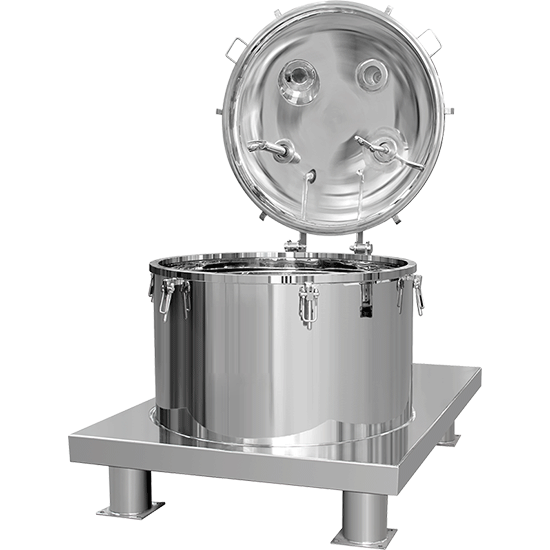

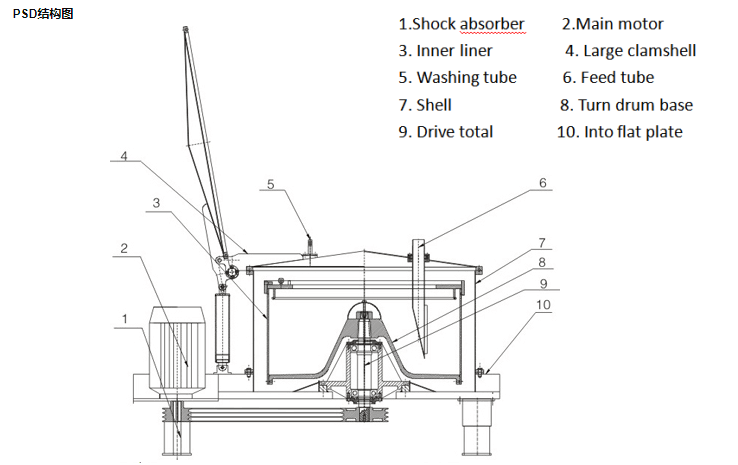

- Structure: Shell is equipped with clamshell, feed tube, washing tube, viewing mirror, exhaust port, lighting hole; Closed structure, drum and shell, clamshell and other parts are made of stainless steel material (SUS404).

- All fasteners are stainless steel parts

- Transmission and braking: ordinary motor (or explosion-proof motor) + inverter + energy consumption braking

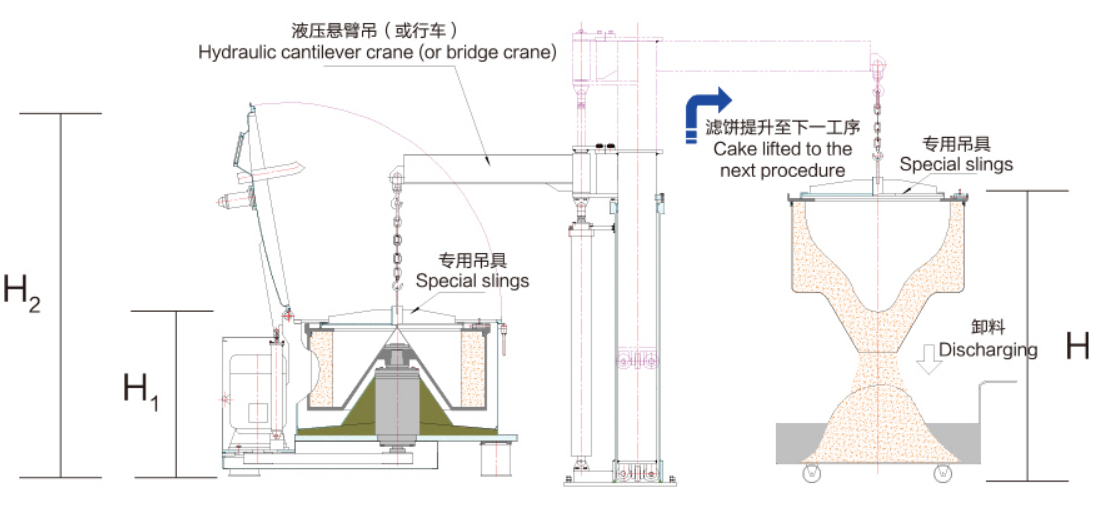

- Electric control device (control box) 5. Fluid damped shock absorber 6. The machine is equipped with a set of special spreader

Products Description

PSD type centrifuge adopts mechanical assisted discharge, which not only has the characteristics of high efficiency of automatic scraper centrifuge, but also has the advantages of wide applicability of unloading centrifuge, advanced product structure design, small footprint, low failure rate, and high cost performance.

PSD centrifuge is an improved product based on SS type tripod upper discharge centrifuge. In addition to retaining the advantages of SS centrifuge, it also significantly reduces the labor intensity, fast discharge, easy to clean the filter bag, improves the production efficiency, and avoids the pollution and dispersion of the finished product caused by manual discharge.

Product Structure

Standard form of manufacture

Matching device

Clean the spray system

Nitrogen protection system

According to the anti-corrosion requirements of the user's separated materials, the corresponding stainless steel material (SUS304, 316, 316L, etc., or titanium (TA)) is used. Overactuating protection

Open cover protection device

Field explosion-proof button

Work Program

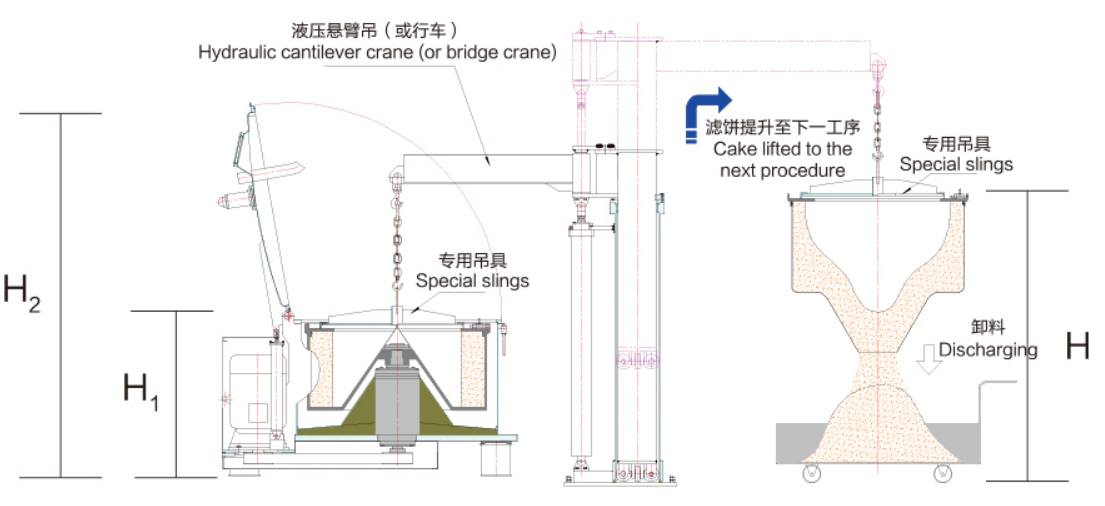

PSD centrifuges are closed type, intermittent operation, lifting bag off-site discharge of filtration equipment. The material is added to the drum from the upper part, the liquid phase passes through the filter medium and is discharged from the machine under the action of centrifugal force field, and the solid phase is trapped in the drum. After shutdown, the liquid baffle and filter bag are lifted out together with the lifting tool. Unloading to site. It has the characteristics of smooth start, adjustable separation factor, large capacity, high efficiency, convenient operation, fast discharge, good safety performance, clean environment and low labor intensity. The PSD type centrifuge eliminates the traditional hanging leg, adopts the plate counterweight and the high viscosity damping vibration isolator to absorb the vibration, and has no foundation installation.

Parameter

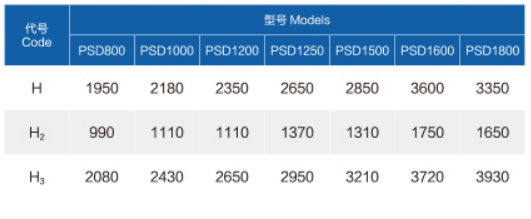

Framework

Features

Low labor intensity and high efficiency: equipped with a hydraulic jib crane, it can be mechanically unloaded.

The grains are not easy to break: the special spreader is used for overall lifting and unloading.

Easy to replace the filter cloth: unique quick-release structure trap plate.

Cover opening method: hydraulic lid opening, mechanical assistance lid opening.

Frequency conversion control: smooth start-up, adjustable separation factor.

Frequency conversion control: smooth start-up, adjustable separation factor.

Smooth operation: The center of gravity of the machine is low, and the liquid damping and damping device is adopted, which can be configured with a variety of configurations such as material layer control device, atomized washing tube, CIP online cleaning system, explosion-proof mirror lamp, etc.

It has multiple safety protections: nitrogen protection system, vibration protection, cover opening protection, overload protection, electromechanical interlocking, etc.