- Description

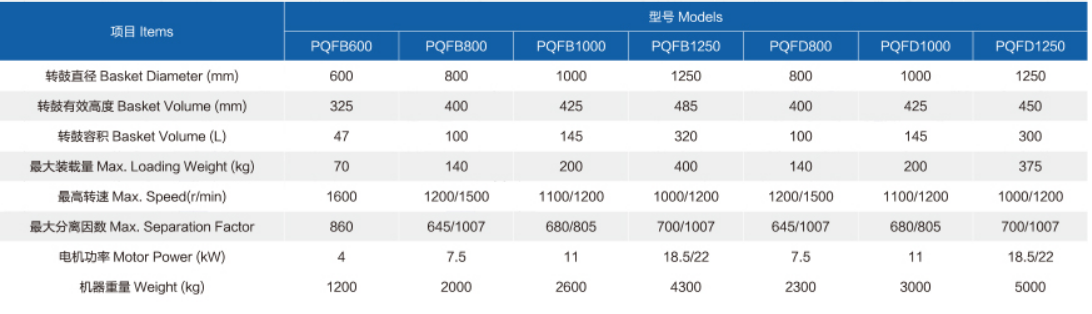

- Parameter

- Features

- Related Products

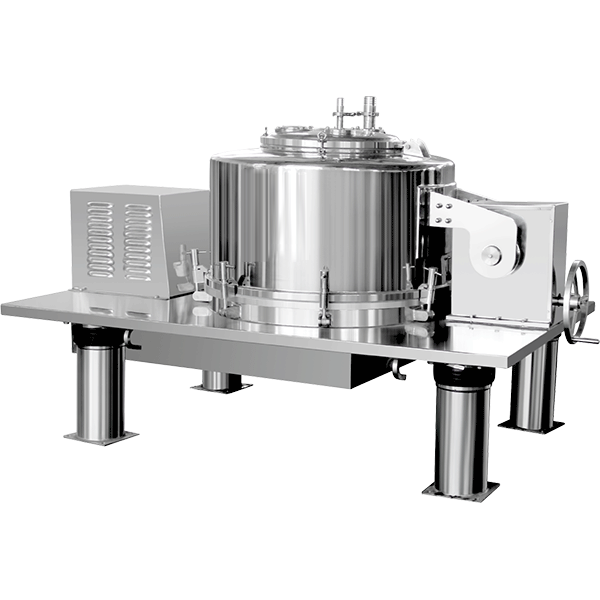

Description

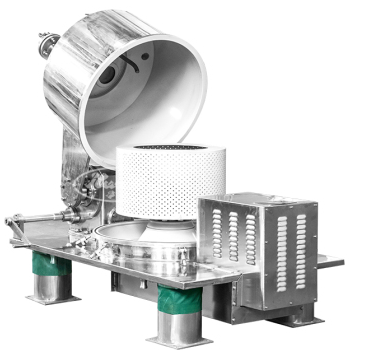

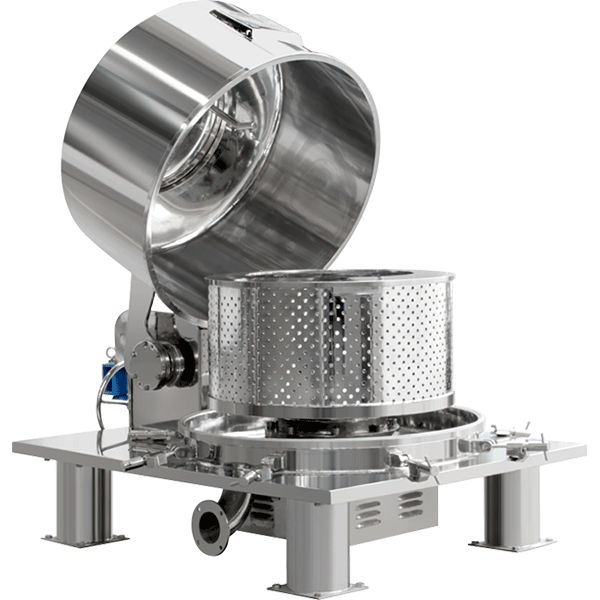

Product Description

PQFB series centrifuge is a kind of hygienic solid-liquid separation equipment suitable for clean area production, which is widely used in pharmaceutical, food, fine chemical and other industries, with beautiful structure, high production process, stable operation, easy maintenance and other characteristics, in line with GMP specifications and high hygiene standards.

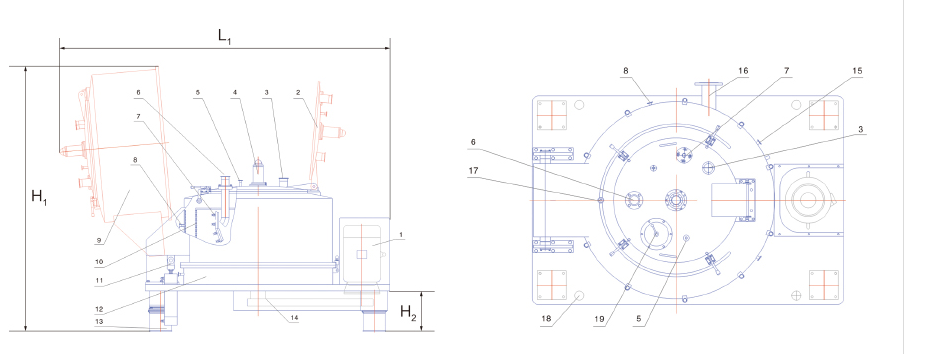

Product Structure

Product Parameter

Main Features

1, good corrosion resistance: the part in contact with the material is made of stainless steel, corrosion-resistant alloy or anti-corrosion coating.

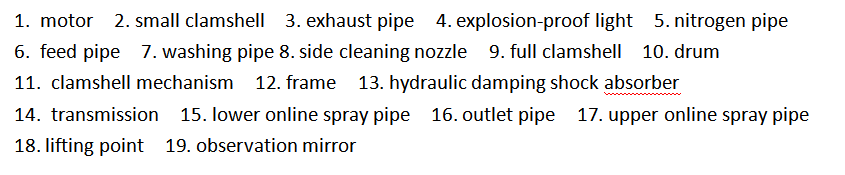

Parameter

|

Model |

Drum diameter(mm) |

Drum volume(L) |

Maximum loading limit(Kg) |

Drum speed(R/min) |

Separation factors |

Motor power |

Dimensions(mm) |

The weight of the whole machine(Kg) |

|

PQSB800 |

800 |

100 |

135 |

1200 |

645 |

5.5 |

1900x1350x1300 |

1800 |

|

PQSB1000 |

1000 |

150 |

200 |

1000/1200 |

560/806 |

11/15 |

2050x1500x1350 |

2200 |

|

PQSB1200 |

1200 |

200 |

280 |

960 |

620 |

15 |

2450x1700x1675 |

3200 |

|

PQSB1250 |

1250 |

280 |

400 |

960 |

645 |

18.5 |

2450x1700x1675 |

3500 |

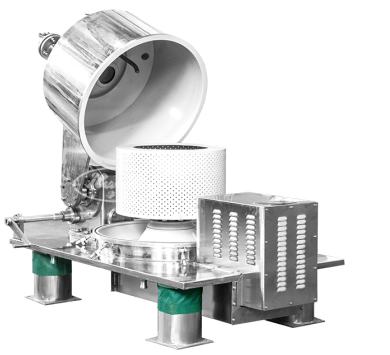

Features

1. Good corrosion resistance: the part in contact with the material is made of stainless steel, corrosion-resistant alloy or anti-corrosion coating.

2. Easy maintenance: full clamshell design, flip angle > 90°, the overall drum is exposed, which is convenient for all-round internal cleaning and filter cloth replacement.

3. All-round on-line cleaning and disinfection: equipped with CIP on-line cleaning system, it can complete all-round cleaning and disinfection of the inner cavity, ensuring the cleanliness requirements and meeting GMP specifications.

4. Advanced structural design: the modular closed space structure design is adopted to avoid pollution caused by belt wear, dust and external foreign bodies.

5. Wide range of application and strong versatility: it can be used for the separation of suspension with solid phase as granularity, and can also be used for the separation of fibrous materials.

6. The grains are not easy to break

7. Multiple safety protection: nitrogen protection system, liquid sealing device, air sealing device, vibration protection, cover opening protection, overload protection, electromechanical interlocking, etc.