- Description

- Parameter

- Features

- How it works

- Related Products

Description

Product Description

This series of products are batch batch processing separation equipment, after discharge, the filter bag is in the regenerative state, good filtration effect, high efficiency, effectively reduce the impact of residual cake layer on material filtration performance, avoid cross-contamination of material separation, meet the requirements of GMP and FDA, can realize remote intelligent control automatic production and online fault diagnosis.

PLD series suction bag bottom discharge scraper centrifuge is a new product independently developed by our company with complete independent intellectual property rights. This series of centrifuge retains the main functions of LGZ series such as solid-liquid separation and scraper discharge, and increases the function of pulling filter cloth to remove residual solid cake, and the removal rate is higher than 99%. The PLD series avoids the crossing and mixing of different batches of separated products, and also eliminates the influence of residual solid cake on the basket wall. It is mainly used in the solid-liquid separation process of crystalline materials in pharmaceutical, food, monosodium glutamate, chemical and other industries.

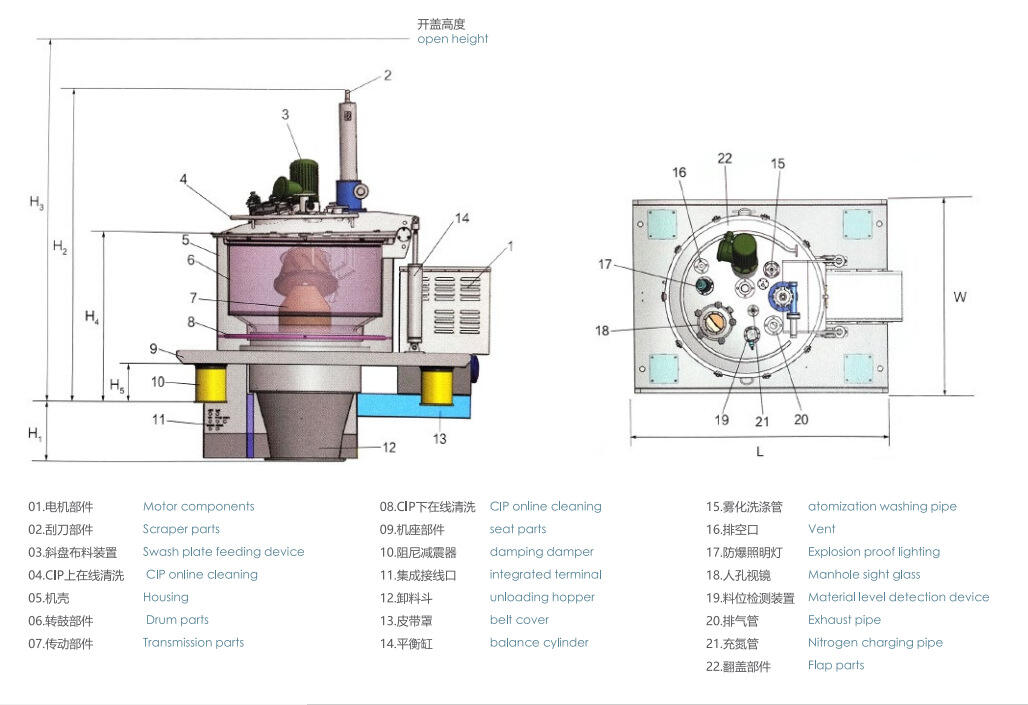

Product Structure

It can be widely used to separate the suspension containing particles, but also fibers, especially the highly sticky, containing micro particles, poisonous and flammable materials, like antibiotics, vitamins, and minerals, salts, gourmet powders, foodstuff additives, amylum, sugar, chemical flavors, thiamin, plasters, sodium sulfate, bluestone, potassium chloride, borax, dyestuffs, pigment, resin, pesticides, and environmental protection. The centrifuge is highly automated, has large capacity and can be remote-controlled. It is mainly used in the solid-liquid separation process of crystallized materials in such industries as pharmacy, food, gourmet power and chemistry.

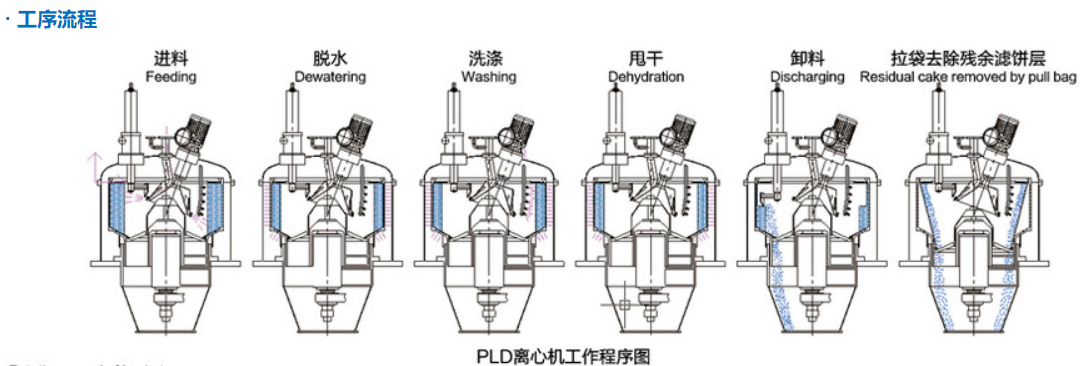

Work Program

Working principle

The material to be separated is added to the high-speed rotating centrifuge drum through the feed pipe. Under the action of the centrifugal field, the material is filtered through the filter cloth, the liquid phase is discharged through the outlet pipe, and the solid phase is trapped in the drum. When the drum is filled with material, stop the feed after dewatering; The cake is washed while the washing liquid is filtered out. The centrifuge continues to spin and the cake is dried. After the filter cake meets the separation requirements, the centrifuge slows down, and the filter cake is scraped down by the scraper and discharged from the bottom of the machine. The centrifuge then slows down, and the pneumatic bag pulling device moves up and down to shake off the residual filter cake and achieve complete removal of the filter cake.

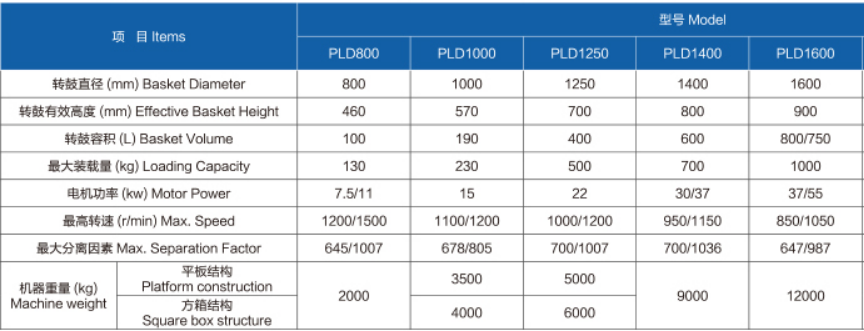

Product Parameter

Main Features

More smooth discharge

The automatic scraping device has the function of speed regulation and distance adjustment, and the scraper adopts a variety of structural design such as double blade (wear resistance: alloy blade, wear resistance coating) The cutting Angle is optimized, the scraping resistance is small, and the layering scraping technology can be used for harder materials.

Run more smoothly

Using liquid damping vibration reduction technology, no foundation installation form, effectively reduce centrifuge vibration, easy to install and repair the machine. Frame square box design, increase chassis weight, reduce centrifuge center of gravity, reduce vibration speed.

Quick replacement of filter bag

Detachable rotary drum liquid block design, self-locking reliable, scientific filter cloth fixed module design (tightening device + quick loading structure), can quickly complete the filter cloth replacement.

Fully machined drum

100% weld flaw detection, high processing accuracy, large filtration area, conducive to ultrafine particle filtration.

Completely enclosed construction

The material and transmission are completely isolated to meet the protection of nitrogen filling inside the equipment, effectively avoid material pollution, and ensure personnel safety.

Multiple security protection and protection

It has over vibration protection, over current protection, temperature control protection, scraper in-situ protection, scraper stroke protection, open cover protection, interlock protection, scraper blocking protection, nitrogen protection, etc.

Configurations

◇External construction: Multiple constructions including big hinged cover, fully hinged cover and flat cover

◇Feed type: inclined feed disk, side feed, middle feed pipe and material level detection device

◇Scraper discharge: Pneumatic, hydraulic and liquid-phase skimming disc

◇Motor drive: Common motor, inverter-duty motor and explosion-proof motor

◇Safety protection: Nitrogen protection (anti-explosion) system, vibration protection, temperature protection, electric-mechanical

interlocking, speed monitoring and overload protection.

◇CIP system: Cleaning ball and spray pipe

◇Washing mode: Atomized nozzle rinsing, feed disk washing, pulse type washing

◇Nitrogen protection system: Automatic control device, hydraulic sealing device and gas-liquid separator.

Product Display

Easy to use :The structure is reasonable and the technology is mature. Easy to install and operate. It can save labor costs.

Reliable quality:Detachable rotary drum liquid stop plate design Optimized cutting Angle, low scraping resistance Low vibration, low noise, smooth discharge High processing precision, large filtering area

Production maturity :Many years of professional production of centrifugal equipment The factory has its own production line The factory equipment has been strictly inspected

Make to order :Our products have comprehensive specifications In addition to regular products Can also be customized according to customer needs Products of all sizes

Fine workmanship and excellent quality

Six advantages to provide you with a better purchase experience

factory-operated:The factory has its own production line

Parameter

|

Model |

PLD800 |

PLD1000 |

PLD1250 |

PLD16000 |

|

Drum diameter(mm) |

800 |

1000 |

1250 |

1600 |

|

Drum volume(L) |

100 |

175 |

300 |

775 |

|

Maximum loading limit(kg) |

125 |

235 |

380 |

1050 |

|

Drum speed(R/min) |

1200/1500 |

1000/1200 |

970 |

850 |

|

Separation factor |

645/1008 |

560/806 |

658 |

647 |

|

Motor power(kw) |

7.5/11 |

11/15 |

22 |

37 |

|

Dimensions(mm) |

1800×1200×2300 |

2000x1500x2250 |

2400x1800x2047 |

3000×2200×2700 |

|

Machine weight(Kg) |

2200 |

3500 |

4500 |

9500 |

Features

1. Smoother discharge

The automatic scraping device has the function of speed regulation and distance adjustment, and the scraper adopts a variety of structural designs such as double-edged (wear-resistant: alloy blades, wear-resistant coatings, etc.), optimizes the cutting angle, and the scraping resistance is small, and the layered scraping technology can be used for harder materials.

2. Run more smoothly

The liquid damping and vibration reduction technology is adopted, and the non-foundation installation form effectively reduces the vibration of the centrifuge and facilitates the installation and maintenance of the machine.

The square box design of the frame increases the weight of the chassis, reduces the center of gravity of the centrifuge, and reduces the vibration velocity.

3. The filter bag is quick to replace

Detachable drum liquid barrier design, self-locking and reliable, scientific filter cloth fixing module design (tensioning device + quick assembly structure), can quickly complete the filter cloth replacement.

4. Fully processed drum

100% weld flaw detection, high processing accuracy, large filtration area, conducive to the filtration of ultra-fine particles.

2. Fully enclosed structure

The material is completely isolated from the transmission, which meets the internal nitrogen filling protection of the equipment, effectively avoids material pollution, and ensures the safety of personnel.

6. Multiple security protection and guarantees

It has over vibration protection, overcurrent protection, temperature control protection, scraper in-situ protection, scraper stroke protection, cover opening protection, interlock protection, scraper lockdown protection, nitrogen protection, etc.

How it works

The material to be separated is added to the high-speed rotating centrifuge bowl through the feed pipe, and under the action of the centrifugal field, the material is filtered through the filter cloth, the liquid phase is discharged through the outlet pipe, and the solid phase is trapped in the bowl. When the drum is filled with materials, stop feeding and deliquidating; The filter cake is washed and the washing liquid is filtered out. The centrifuge continues to spin and spin the cake dry. After the filter cake meets the separation requirements, the centrifuge slows down, and the filter cake is scraped off from the bottom and discharged from the machine through the scraper. The centrifuge is slowed down again, and the pneumatic bag pulling device moves up and down to shake off the residual filter cake and realize the complete removal of the filter cake.