- Description

- Related Products

Description

- System loading: A pre-loaded closed filter bag is placed into the basket and the system is sealed to begin the cycle.

- Program Menu: The 'Spray Wash' or 'Agitation Wash' program is selected on the program manu where the RPM and cycle times are set to the operator's specifications.

- Alcohol Fill: Alcohol is pumped from source tank into the centrifuge via an inlet valve or spray nozzle.

- The Wash cycle: The plant material undergoes either a spray wash or an agitated wash with a set number of bi-directional agitations.

- System Draining: When the wash cycle is complete, the outlet valve is manually opened and the liquid drained. The alcohol wash is pumped to a properly rated storage tank for further processing.

- Spin Dry Cycle: The 'Spin Dry' program is selected on the program and the drying cycle is started. The wet plant solids are spun dry of the remaining alcohol mixture within.

- System Unloading: when the dry cycle is complete, centrifuge is unloaded by taking the filter bag out from the basket.

- Repeat Process.

Product Description

PBZ series is designed according to GMP standard and environmental protection requirements of fully enclosed manual up-discharge filter centrifuge, with a wide range of material application. It has good applicability to high temperature, large viscosity, small particle size, all kinds of difficult to separate suspension, fibrous materials, and the minimum particle size of separation is 1μm. Often because of large separation factor, simple structure, excellent performance and other characteristics, it is often selected as a testing machine by various research institutions.

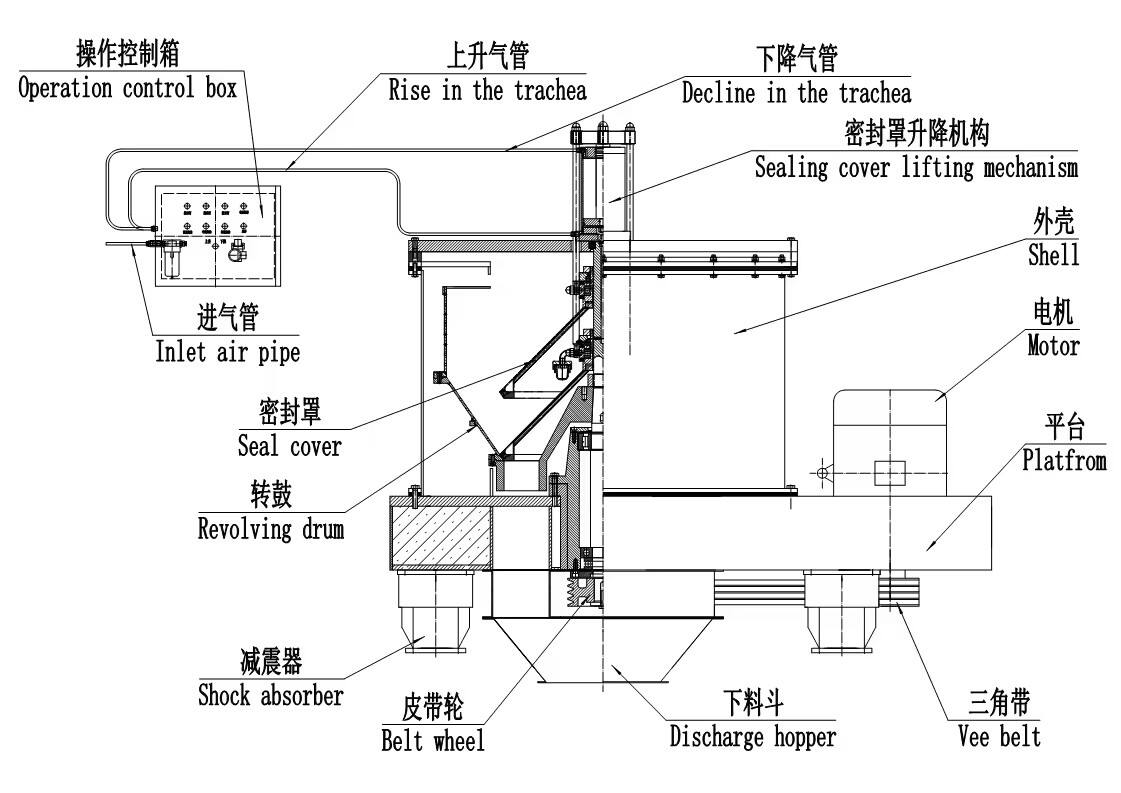

Product Structure

Working principle

Under the action of centrifugal force, the material tends to turn the drum wall, and the liquid phase passes through the filter media covering the drum wall through the drum wall filter hole, tends to the inner wall of the shell and falls into the chassis, and is discharged through the liquid outlet. The solid phase material remains in the drum and can be fully washed, so as to complete the separation of solid and liquid, open the shell flap after shutdown, after manual unloading is completed, close the upper flap, and lock can start the next working cycle.

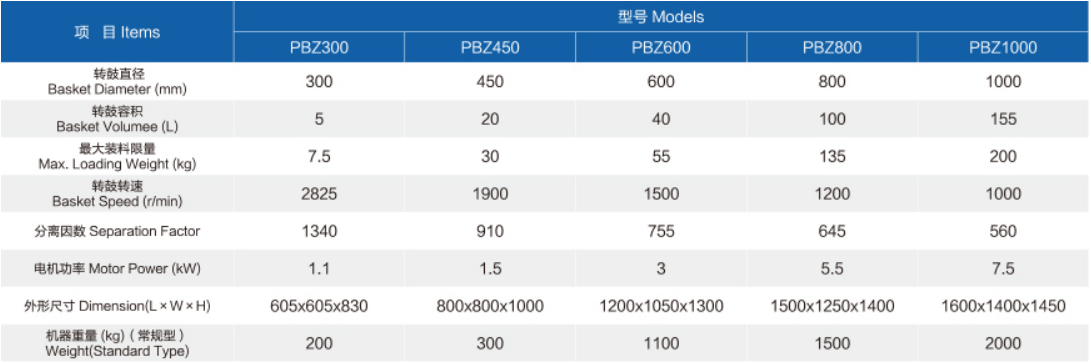

Product Parameter

Main Features

Meet GMP standards: fully closed structure, effectively avoid material pollution. CIP online cleaning system can be configured to achieve comprehensive online cleaning.

Large open cover structure, easy discharge, easy replacement of filter bag.

Smaller footprint, easy maintenance, low failure, longer service life.

High separation factor, good separation effect.

Light structure, simple operation, low center of gravity, small vibration, more stable operation.

The grain is not easily broken and has a wide range of application.

Multiple security protection configuration, frequency conversion control, can achieve stepless speed change.

Working Steps

Product Display

Why Choose Us

Many years of experience in chemical industry

Industry and trade integration, own factory

Large inventory

Sophisticated production equipment

Skilled technical team

Perfect after-sales service

Production Site