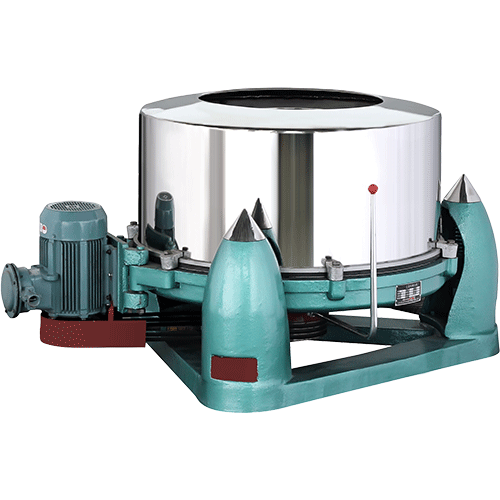

Centrifuge CTL type centrifugal extractor

Product Description

Product Structure

Work Program

The centrifugal extractor mainly includes two working processes, namely mixed mass transfer and centrifugal separation. The centrifugal extractor can automatically and continuously complete the mixing and separation process.

Mixed mass transfer

After entering the centrifugal extractor, the water phase and the organic phase are shear dispersed into tiny droplets by the high-speed rotating drum or blade, so that the two phases fully contact, so as to achieve the purpose of mass transfer.

Centrifugal separation

The mixed liquid formed by the mixing of water phase and organic phase enters the rotary drum. Driven by the rotary drum and its spoke plate, the mixed liquid rotates synchronously with the rotary drum at high speed to generate centrifugal force. Under the action of centrifugal force, the dense liquid gradually moves away from the center of the drum and toward the wall of the drum in the upward flow process. The less dense liquid gradually pushes the wall toward the center. Finally, the two-phase liquid is thrown into the collection chamber through their respective channels, and the two phases flow out from the respective collection chamber, thus completing the two-phase separation process.

Product Parameter

Model |

CTL150 |

||||||

Drum Diameter(mm) |

150 |

||||||

Handing capacity(L/H) |

100~100 |

||||||

Motor voltage(V/AC) |

380 |

||||||

Motor Power(kw) |

2.2 |

||||||

Inlet and outlet(mm) |

Φ34/Φ34 |

||||||

Total Weight(kg) |

250 |

||||||

Physical Size(mm) |

500*500*1200 |

||||||

Main Features

The equipment is small in volume, short in balance time and less in extractant tank.

Large processing capacity and low power consumption.

High degree of automation, simple operation.

The extraction system can be closed and the operating environment is good.

The equipment has compact structure and small footprint.

Vertical direct motor drive, compact structure.

Can adapt to intermittent or continuous operation.

Small volume, save extractants, solvents or detergents

The speed and mixing method are convenient and can adapt to the requirements of different extraction systems.

The upper suspension structure, no bottom bearing and mechanical seal, no leakage risk, no wearing parts, simple and convenient maintenance.

Replace the heavy phase weir plate without disassembling the motor and bearing.

Typical application

This type of centrifugal extractor is widely used in the field of liquid extraction or separation without solids or containing a small amount of solid systems. Such as:

oil-water separation (water and salt removal of crude oil, heavy oil, diesel oil, etc.)

Pharma

Chinese medicine extraction (tea extract of thetophenol, Chinese medicine extract of garlic oil, etc.)

pesticide (malathion extraction)

Bioengineering (extraction of nutrient solution and interferon)

Chemical \ Fine Chemical (Catalyst extraction, etc.)

hydrometallurgy (extraction of nickel, copper, uranium and other rare metals by multi-stage extraction and reverse extraction)

Food (separation or extraction of edible oil, essence, refined oil, food color, etc.)

Fragrance industry

Printing and dyeing industry (printing and dyeing wastewater treatment and recycling)

Environmental protection industry (using multi-stage extraction, reverse extraction and other processes to treat phenol-containing sewage, oil-water separation in ship sewage, oil-water separation, groundwater separation or extraction and purification)

Cosmetics industry (extract nutrients, etc.)

liquid/gas separation (removal of bubbles from liquid phase, etc.)

- Description

- Related Products

Description

Product Description

Product Structure

Work Program

The centrifugal extractor mainly includes two working processes, namely mixed mass transfer and centrifugal separation. The centrifugal extractor can automatically and continuously complete the mixing and separation process.

Mixed mass transfer

After entering the centrifugal extractor, the water phase and the organic phase are shear dispersed into tiny droplets by the high-speed rotating drum or blade, so that the two phases fully contact, so as to achieve the purpose of mass transfer.

Centrifugal separation

The mixed liquid formed by the mixing of water phase and organic phase enters the rotary drum. Driven by the rotary drum and its spoke plate, the mixed liquid rotates synchronously with the rotary drum at high speed to generate centrifugal force. Under the action of centrifugal force, the dense liquid gradually moves away from the center of the drum and toward the wall of the drum in the upward flow process. The less dense liquid gradually pushes the wall toward the center. Finally, the two-phase liquid is thrown into the collection chamber through their respective channels, and the two phases flow out from the respective collection chamber, thus completing the two-phase separation process.

Product Parameter

Model |

CTL150 |

||||||

Drum Diameter(mm) |

150 |

||||||

Handing capacity(L/H) |

100~100 |

||||||

Motor voltage(V/AC) |

380 |

||||||

Motor Power(kw) |

2.2 |

||||||

Inlet and outlet(mm) |

Φ34/Φ34 |

||||||

Total Weight(kg) |

250 |

||||||

Physical Size(mm) |

500*500*1200 |

||||||

Main Features

The equipment is small in volume, short in balance time and less in extractant tank.

Large processing capacity and low power consumption.

High degree of automation, simple operation.

The extraction system can be closed and the operating environment is good.

The equipment has compact structure and small footprint.

Vertical direct motor drive, compact structure.

Can adapt to intermittent or continuous operation.

Small volume, save extractants, solvents or detergents

The speed and mixing method are convenient and can adapt to the requirements of different extraction systems.

The upper suspension structure, no bottom bearing and mechanical seal, no leakage risk, no wearing parts, simple and convenient maintenance.

Replace the heavy phase weir plate without disassembling the motor and bearing.

Typical application

This type of centrifugal extractor is widely used in the field of liquid extraction or separation without solids or containing a small amount of solid systems. Such as:

oil-water separation (water and salt removal of crude oil, heavy oil, diesel oil, etc.)

Pharma

Chinese medicine extraction (tea extract of thetophenol, Chinese medicine extract of garlic oil, etc.)

pesticide (malathion extraction)

Bioengineering (extraction of nutrient solution and interferon)

Chemical \ Fine Chemical (Catalyst extraction, etc.)

hydrometallurgy (extraction of nickel, copper, uranium and other rare metals by multi-stage extraction and reverse extraction)

Food (separation or extraction of edible oil, essence, refined oil, food color, etc.)

Fragrance industry

Printing and dyeing industry (printing and dyeing wastewater treatment and recycling)

Environmental protection industry (using multi-stage extraction, reverse extraction and other processes to treat phenol-containing sewage, oil-water separation in ship sewage, oil-water separation, groundwater separation or extraction and purification)

Cosmetics industry (extract nutrients, etc.)

liquid/gas separation (removal of bubbles from liquid phase, etc.)