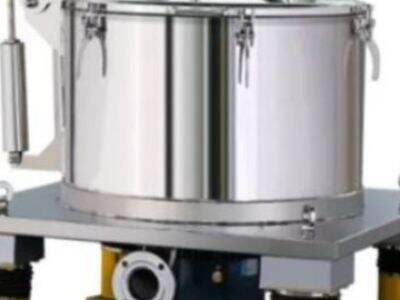

There are multiple factors to consider when choosing the right centrifuge for your facility. Coupled with this is the fact that the outlet of the centrifuge has to discharge materials after the separation is done, and this is one of the most critical aspects. One of the most common choices for many companies is the use of a plate top discharge centrifuge. That said, not all plate top discharge centrifuges are created equal. You have to pick one that is have a good build and great design so that you can transform your writing experience.

Why Good Design Matters

One can make a huge difference in how well a plate top discharge centrifuge will perform. A well-designed and good quality centrifuge helps improve separation of the materials and speeds up the process significantly. Which means you can learn faster and do more in less time. Moreover, a well-built centrifuge requires less maintenance and is less likely to break down than one that is poorly built. For example, a centrifuge created with rust-proof, durable materials will last much longer and require less repairs than a cheap or poorly made centrifuge. Why is this important — less downtime means that you can maintain your workflow.

Thinking About Costs

Cost of purchase is an factor when looking at a plate top discharge centrifuge, but it’s not the only factor worth considering. You also have to consider what it will take to operate and maintain it long-term. You can save lots of money in the long run by picking a reliable and energy-efficient centrifuge. That means it won’t be a power hog, and could save you money on power bills. It’s also ideally a good idea to choose a centrifuge that can be easily repaired and maintained, since you don’t want it to sit around not working for a lot of time. SPIR is about taking steps to reduce the amount of time the SPIR is out of service for repairs (while also potentially saving on repair costs), to keep operations running smoothly.

Maintaining Quality and Consistency

The way that the centrifuge is configured will determine the quality of the products that you receive. Key factors such as bowl speed, dispense rate, and feed rate all need to be articulated precisely. For instance, a centrifuge with a high bowl speed is a good way to get better separation of the materials and a drier product, which is generally desirable. But if you dump materials into it too fast, it can jam up, which would slow things down. It’s all about finding that balance in those spaces so you can get optimal results.”

Choosing the Centrifuge That’s Right For You

With a plate top discharge centrifuge selection, consider the specific requirements of your processes. Different factors are crucially important: type of materials, quality of final products that you want, regular production volumes, etc. You may also want to consider the manufacturer/reputation of the company that produces the centrifge. Seek out a company known for quality and postpurchase support. That way, you are certain to invest in a quality, durable machine that fits your particular needs.

Finally, with so many other factors to take into account, finding the right plate top discharge centrifuge for your facility can be a big decision. By leading with key design and construction considerations, cost considerations, and considerations around the configurability of your final products, you can ensure you select a centrifuge that will give you top performance, product quality, and uniformity. If you need such solution trust us; we create high-quality top discharge centrifuge, plate centrifuge, to suit the specific customer. Call us now to discover more about our products and how we help you achieve an optimal separation process!