These separator machines have a variety of uses in industries, however, one of the main applications is separating solids from liquids in order to remove solid organic matter. Here are several reasons why choosing the proper centrifuge filter bag is important in ensuring smooth operation and quality work. This article will discuss the kinds of filter centrifuges available, criteria for choosing a filter centrifuge, aligning the size and performance of a filter with its application requirements, including examining maintenance and operational costs, and selecting a filter centrifuge for maximum efficiency and productivity.

Types of Filter Centrifuges

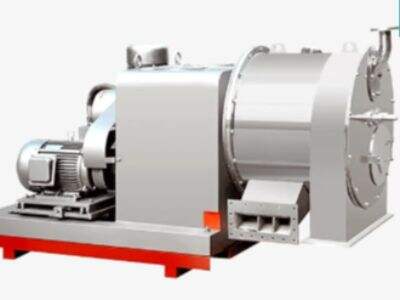

There are different types of filter centrifuges available in the market, and each filter centrifuge is designed for specific operations. The most popular category includes basket centrifuges, pusher centrifuges, and peeler centrifuges.

Basket centrifuges are effective for separating big amounts of solids and liquids, like chemicals, medicines, and food products.

They work continuously and are very good for removing water from small particles.

Centrifuges of the peeler type are optimal for removing solid crystals from identical liquids.

Understanding the differences between these types is enormously crucial for selecting the right filter centrifuge for your company.

Factors to Consider When Selecting a Filter Centrifuge

Specifications to Consider when Choosing a Filter Centrifuge These considerations include what materials are to be separated, the quantity of material required to be processed, the level of efficiency needed in the segregation process, and whether space is available for the equipment. Additional considerations include operating temperature and pressure, as well as possible automation. Taking a close look at these angles, you can select a filter centrifuge that meets your needs and keep everything running smoothly.

Aligning Size and Performance Requirements

A company's best choice for a centrifugal filter will be a balance with its size and performance that matches its business. It is vital that you select a centrifuge that will process the material volume you require within a timeframe suitable for you. In addition, the centrifuge must be capable of achieving the necessary separation rates to achieve quality. You will be sure to have a great performance, and a very high productivity on your work through the size and performance needed matching.

Maintainance and Operating Cost Check

Apart from size and performance, it is very essential to check the operational and maintenance cost of a filter centrifuge. Consider how often it requires maintenance, whether spare parts are available, and how much energy it consumes. Choose a centrifuge that will not cost you an arm and a leg in maintenance, tools and running costs over time. If maintenance and operation costs remain low, it leads to efficiency and more profit in business processes.

Filter centrifuge- Selecting an Equipment to achieve Maximum Productivity and Efficiency

Ultimately, selecting the right filter centrifuge will help you get the right efficiency and productive results in your work. Then, you can select a centrifuge that suits your business needs by examining the various types of centrifuges, analyzing features such as size and performance, and comparing maintenance and operational costs. Not only does a good filter centrifuge improve the quality of your products, but it also helps your manufacturing processes work better. To ensure that everything goes smoothly and that you get the most out of your business, get a quality filter centrifuge.

Finally, Correct filter centrifuge selection for your business is essential to ensure good efficiency and productivity. Making a well-informed choice that benefits your future business entails understanding the various continuous filtering centrifuge types, evaluating size and performance requirements, examining service and operational costs, and selecting a centrifuge for optimal efficiency. Rely on a trustworthy company for quality filter centrifuges that are specially designed for your industry and can enhance your work performance. You can make your processes easy, improve product quality, bring success in your industry with the perfect filter centrifuge.